|

| Athena Tray Sealers Machines |

The global thermoformed packaging market is expanding rapidly. Growing acceptance of thermoformed packaging, increasing range of applications in food and pharmaceutical industry, high usage of thermoformed shallow trays in bakery applications are some of the factors stimulating the market growth globally.

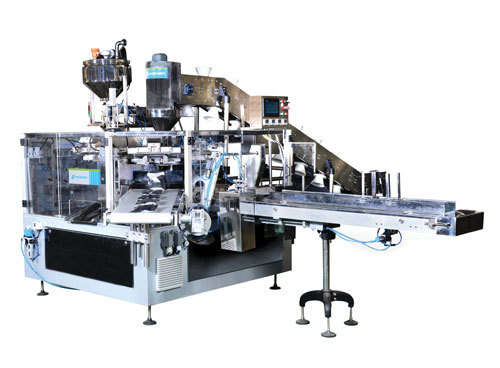

Pre-formed tray sealing with modified atmosphere (MAP) increases useful life of product if compared to traditional packaging (stretchable film). The automatic sealing machinemodel Athena from Tecnovac is capable of packaging in modified atmosphere any combination of compatible trays and top film studied for such applications.

Athena packages fresh, refrigerated, processed or frozen food products at a full range of output rates. Athena produces attractive, leak-proof, tamper-evident packages with greater seal integrity and extended shelf life. They are perfect for all types of prepared food, meat, poultry, seafood, produce and snack packaging as they delay microbiological spoilage & deterioration of the product, offering perfect exposure on supermarket shelves.

Thanks to Athena’s strong stainless steel structure, easy maintenance and conformity to hygienic requirements, this machine is ideal for use in small and medium sized companies. The aluminium mould is made each time according to the customer’s requests in order to obtain absolute precision in the details of the packaging.

To double productivity, consider the Athena Dual Drive. This machine is an integrated, double chamber version which can have two identical moulds to double productivity. At the same time the machine allows the reduction of the waste film (no waste film in the area between the two chambers).

High flexibility is ensured as the machine allows the packing of trays with two different tools since the two chambers can work alternatively. Both tools can remain constantly heated and therefore always ready-to-use. The machine also offers the possibility of performing Skin + Standard Top Seal application without manual operations and changeovers and with only one passage of the trays into the machine.

The price-quality combination and Tecnovac’s high international standards make Athena the best solution for RTE / RTC packaging. In India, Athena is brought to you by Nichrome, the leading packaging solutions provider, so customers are assured sound sales & service support. For snack packaging, Namkeen packaging, RTE/RTC packaging, Nichrome offers a wide range of automated packaging machines andend-to-end integrated packaging lines.

Visit for more:www.nichrome.com