Sugar is one of the world’s most consumed products.

Every cuisine in the world needs sugar and it is sold practically in every

supermarket or grocery store. Sugar is mainly sold in granulated form called ‘white

sugar’ or ‘regular sugar’. It is also sold in other forms like brown sugar, raw

sugar, liquid sugar etc.

Packaging of sugar is one of the most

important aspects of the sugar retail chain. Sugar being a water soluble

product, needs complete protection from water. It also needs protection from odour,

ants, oxygen, moisture, vapour and humidity. The objective of sugar

packaging is not just confined to protection and convenience, but also to

creating an attractive display and promotion of the brand.

Excellent quality packaging is an absolute must for

a product like sugar, which has high solubility and long shelf life. Sugar

packaging is required for the convenience of both sellers and the

buyers, and for safe transportation and handling. Good quality packaging assures

longer shelf life of sugar.It also facilitates brand identification. Sugar

packaging for retail is generally done in 1, 2, 5 and 10 Kg. pouches and bags.

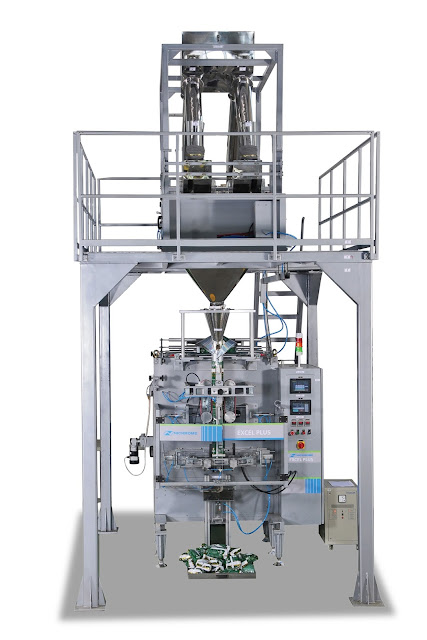

A typical sugar

packaging process involves operations like conveying, weighing, filling,

closing and sealing. Nichrome offers

a complete range of automated equipment suitable for packaging different pouch sizes.

Our machines are designed for accurate weighing, safe handling and packaging of

sugar. The machines are designed to handle variety of packing materials and

types or forms of packaging, such as stand up pouches, spout pouches, three

side sealed bags, pillow bags, etc. The packaging line is fully automatic, with

user friendly controls; equipment is easy to clean and maintain.

Nichrome is one of the leading manufacturers of

high-tech and innovative sugar

packaging machinery. We offer complete automated solutions for entire

operations of sugar packaging,

starting from bag making, weighing and filling sugar, sealing the bags and

discharging the packaged bags. We also offer machines for pre-made bags with operations

like bag pick-up, opening the mouth of the bag, filling the sugar and sealing

the bag. Our sugar packaging solutions are available in a wide

range of capacities to meet different capacity requirements of sugar

manufacturers.

Our latest range of sugar

packaging machines are designed for the bottom gusseted stand-up

pouches with a resalable zipper, the type of packaging which is gaining

popularity in the consumer market.

The sugar packaging solutions offered by us are extremely

easy to operate and guarantee high performance with minimum wastage and low

maintenance. This makes Nichrome’s

machines cost effective. Our packaging

solutions are designed to help sugar manufacturers to maintain the quality,

taste and hygiene of their product for longer duration. Perfectly packaged

products are always preferred by supermarkets as it minimises their losses

during product handling and storage. Impressive and attractive packaging goes a

long way in achieving brand loyalty in the retail market.