When it comes to flexible packaging solutions, Nichrome’s name instantly comes to mind. A pioneer in pouch packaging machines since 1977, Nichrome has four decades of unmatched experience and expertise in the field.

|

| Oil Packaging Machines |

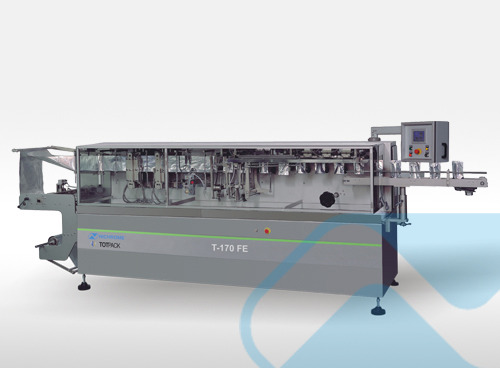

However, Nichrome offers much more. For edible oil manufacturers, Nichrome offers extensive design, manufacturing and installation capabilities for complete packaging lines. Leading edible oil filling machine manufacturer, Nichrome can design end-to-end packaging solutions — including pre-primary packaging machines, primary oil pouch packaging machines, secondary and tertiary packaging machines, all automated and integrated for optimal performance. Based on the customer’s individual requirements and constraints, Nichrome custom-designs complete solutions to deliver the speed, accuracy and economy demanded by modern production.

By automating and integrating packaging lines, manufacturers and packaging companies can improve the rate of production while reducing cost and enjoying quick return on investment. Other benefits include waste reduction and minimization of downtime between runs. Customers also save on manpower costs and avoid human errors.

|

| Edible Oil Packaging Machines |

As a full-service packaging partner, Nichrome combines products, equipment and strategic guidance to deliver smart packaging solutions. That too with single-source convenience! Whether customers are just beginning to automate, augmenting n existing packaging system or looking for turnkey packaging solution, Nichrome has the in-house capabilities to address the challenges and cater to specific needs. Nichrome’s skilled team delivers the insight and expertise to help design, install commission and maintain entire packaging lines.