Gone are the days when the cow was brought to the consumer’s doorstep for milking. So consumers were assured freshness and purity.

|

| Filpack Servo 12K |

It’s a different world today. Growing demand and high cost of milk production has created a need for packaging that conveys the milk safely from cow to consumer. Evolving challenges, concerns and demands for both consumer and distributor have challenged the dairy industry to continuously search for smarter packaging solutions that are not only durable, cost-effective and recyclable, but also use less energy and water.

Criteria for good milk packaging

Milk is an extremely perishable and sensitive product, so it is imperative that the packaging material is effective in preserving its initial quality till it reaches the consumer. It must be tamper-proof and act as barrier to bacterial contamination. However, given changing lifestyles, consumer needs for convenience and hygiene, modern production technology, etc., milk packaging must fulfill other requirements too.

· It should be free from off-flavours

· It should be resistant to UV light

· It should have no physiological effects on the products

· It should possess good mechanical properties (sealing, tensile, structural strength, etc)

· It should possess good oxygen barrier properties

· It should be economical

· It should fit in to the processing line

Evolving packaging trends

The first development for retail packaging was the glass bottle which came at the end of the 19th century. It remained unchallenged till 1933 when the first carton made of waxed paper was introduced.

In the late 1950s, the milk pouch concept originated in Europe, and soon become the rage with its convenience and reduced costs. Polyethylene, particularly LDPE has been used for packing milk. Nowadays, in India milk pouches are formed from LLDPE film of 50–55 μ thickness.

In the 1960s, aseptic packaging was born in Sweden, originally called the ‘Tetra-pack’ system. Aluminium foil is used to provide a barrier against light and gas. This system enhances the shelf life of milk dramatically; if refrigerated, a shelf life of up to one year is possible. No refrigeration is required for at least 3 months.

Innovations in Plastic Packaging

Plastic packaging continues to be the global favourite for milk packaging. Compared to cartons, it helps cut down environmental costs.

In the field of plastic packaging, relentless R&D across the world has resulted in some smart and sustainable innovations. Some of these are:

Milk bag in a jug: This innovation produces 75 percent less waste than traditional milk packaging. Made from LDPE, these milk bags are highly durable and fitted within a reusable and easy-to-pour polypropylene jug. The design ensures a no-leak seal and pours the milk through the spout. With more and more people living with smaller families, plastic packaging makes an ideal solution to stock dairy products while producing much less waste.

Milk bag in a box: It looks like a traditional plastic milk container but is made up of cardboard pulp shaped like a bottle/carton with a low density polypropylene bag on the inside. Its carbon footprint is 48% lower than that of milk bottles made using HDPE. Innovative & sustainable, this green milk packaging also consumes less than 0.5% of the space of traditional milk packaging in a landfill.

Squeezy stand-up pouch with straw: This new, single-serve form of milk packaging is portable, easy-to-use, and more economical than the paper carton. It is a thermoformed stand-up pouch with integrated straw. The squeeze feature facilitates maximum evacuation of milk, and when empty, it compresses into a small mass, making disposal low-cost and efficient.

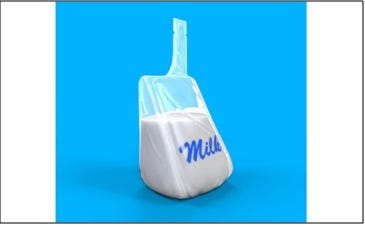

Milk in a flexible pouch: In several countries, especially in the developing world, the dairy industry is also using pouch packaging for milk. Made from LLDPE film, this pouch is reusable, easy-to-pour and produces 75% less waste than conventional milk packaging.

Milk packaging in India

In India, while tetra packs are gaining popularity, the high price point puts them out of reach for most consumers. Milk pouches remain the popular choice, widely used by India’s dairy industry. The pouches are generally made of low-density polyethylene (LDPE) film, but some dairies also use co-extruded LDPE-LLDPE film as it eliminates pin-hole problems. The pouches are formed and filled on form-fill-seal (FFS) machines in capacities of 200, 500 and 1000 ml.

When it comes to sustainability, flexible pouches use less packaging — around 75% less material than other packaging. They are also much lighter in weight, saving resources in transportation costs. The overall reduced cost makes the milk more accessible to more people and new markets.

Conclusion

For milk pouch packaging in India, Nichrome has been blazing trails since 1976. Today, India’s fastest milk packaging machine comes from Nichrome — Filpack Servo 12K which packs an impressive 12,000 pouches per hour. As India’s leading packaging machine manufacturer, Nichrome offers a range of machines and integrated solutions for the dairy industry. To know more, www.nichrome.com