In any industry, downtime is a dreaded word. Nichrome, India’s leading packaging machine manufacturer with four decades of experience in the industry understands this only too well.

|

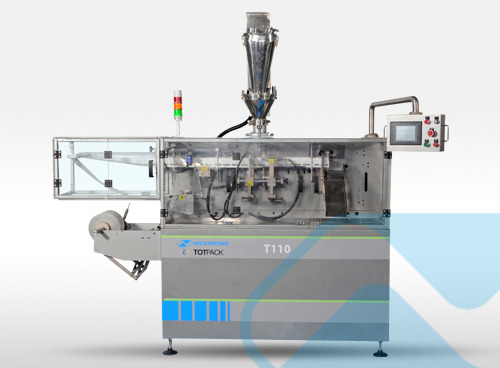

| HFFS Machines HFFS Series T-110 |

That’s why service support is a key element of Nichrome’s offerings. Nichrome’s worldwide service network provides comprehensive services – from preventive and reactive service to upgradation and overhauling. All geared towards ensuring optimized performance, reliability and uptime of Nichrome’s packaging machines.

Nichrome has a team of trained and experienced service engineers to cater to a wide database of installations and routine back-up service. Nichrome makes a special team of service personnel available to cater to more complex assignments of installations and commissioning, retro-fitment jobs and service supports.

The expertise available in the service team is also utilized for trial management at the factory for critical application machines and tested thoroughly as per the client’s requirements before the dispatch.

Nichrome has expert engineers for different regions like Delhi, Kolkata, Mumbai, Hyderabad, Chennai, Cochin, Bengaluru, Ahmadabad, Indore and other parts of India. For immediate overseas calls, Nichrome has service engineers at CIS, Russia & SAARC. For in-time spares availability, there are distributors across the country & overseas.

All the service personnel are centrally trained in technology aspects of machines / product range. The service and spares team also contributes by giving valuable quality feedback to the design department. This feedback assists the design department in upgrading the technology to optimise consumption pattern of spares & consumables.

Moreover, Nichrome organizes workshops/seminars to train customers on a particular technology or sector.

Genuine Spare Parts

A critical aspect of Nichrome’s support is genuine spares. Nichrome values its customer’s investment in its world class automatic packaging machines and strives to ensure maximum protection through use of genuine spare parts.

|

| Genuine Spare Parts |

|

| Genuine Spare Parts |

Spare parts supplied by Nichrome are specifically designed for the particular machines configuration. They are tested and verified for safe use on Nichrome’s pouch packaging machines and come with applicable warranty.

Contact us for more details: http://www.nichrome.com/machines/hffs-machines/