The RTE (Ready-To-Eat) industry is booming. And why not? RTE food offers convenience and variety. It saves time and energy — elements of great value in contemporary India with its changing lifestyle, growing urbanization, increase in nuclear families and rise in disposable income.

The Indian RTE food market is dominated by Mavalli Tiffin Room (MTR), GITS Food Products Pvt. Ltd., Indian Tobacco Company (ITC), Kohinoor Foods and Priya Foods.

Product innovation, branding and attractive packaging have also provided impetus to the RTE industry. The players in the packaged food industry tweak their product offerings to suit the taste of Indian consumers and launch new variants of the products to cater to region-specific demand which have widened their consumer base. The industry players also consider factors like freshness, crispiness and flavor of the product, which the consumers consider important, before launching new products. Newer preservation techniques have led to enhanced shelf life.

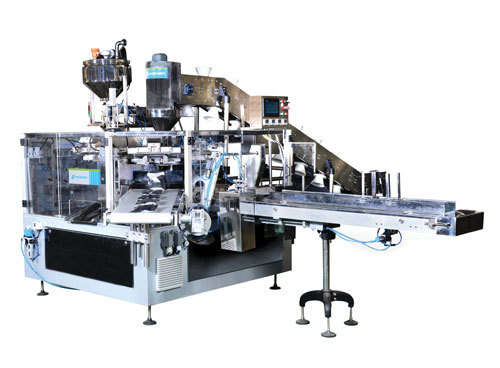

Nichrome’s Totpack Pick-Fill-Seal machine offers the combined benefits of variety, productivity and specialty packaging for ready-to-eat food packaging. The ready to cook packaging machine conveniently packs a wide variety of ready-to-eat and ready-to-cook foods in eye-catching innovative shapes while maintaining freshness of the products. Advanced packaging technology enables 2 or 3 different fillers to dispense multiple types of ingredients in the same pouch.

The Horizontal Form Fill Seal (HFFS) machine is a sturdy, cost-effective solution with multiple filler options. The RTE Filler facilitates the packaging of products such as Palak Paneer, Dal Makhani, Butter Chicken, Biryani, Gravies, Matar Paneer, Punjabi Chhole, Punjabi Kadhi, Rajma Masala, etc.

The Linear/Gate Weigher can be used for vegetable seed packaging while the Servo Auger Filler is suitable for powders like ORS, Pharmaceutical Powder, Spice Powder, Milk Powder, Coffee, Health Drinks, Instant Mixes, Premixes, etc. Multi-Head Weighers are used for snack & Namkeen packaging. Piston Fillers transform the machine into a ketchup packaging machine, ideal for viscous products like pastes, pickles, soup, sauces, ghee, etc.

Other filler options include Cup Filler (for sugar, rice, pulses, etc.) and Gravity Filler/Flow Meter (for liquids like milk, lassi, oil, juices, wines, etc.).

The high-precision Totpack PFS packaging machine is controlled through a PLC with touch-screen interface, and supports a variety of pack/pouch formats. Packing material for preformed pouches include heat sealable laminates like PET/PE, Paper/Alu-foil/PE, Alu/PF, PET/Alu-foil/PE or Co ex films.

All these features and advantages have made Nichrome’s PFS machine the preferred choice of players in the processed food industry – serving speed, efficiency and flexibility to make operations smooth and profitable.

Visit for more: www.nichrome.com

Hello,

ReplyDeleteThanks for sharing information about packaging machine with us. I appreciate to you for this blog. Compak is also known as the best packaging machine manufacturer such as Carton Wrapping Machine Manufacturer

Shrink Wrapping Machine Manufacturer

Stretch Wrap Machine Manufacturer

Stretch Wrapping Machine Manufacturer

Box Wrapping Machine Manufacturer

Pallet Wrap Machine Manufacturer

Pallet Wrapping Machine Manufacturer