In India, and indeed, across Asia, we witness a transformational growth in the packaged food and instant food industry over the past decade or so.

Populous economies like ours are fuelling this growth owing to changing lifestyles, increasing numbers of working professionals and greater disposable incomes. Ready-to-eat instant foods are preferred as they require minimal time to cook and offer great variety. What is more, instant packaged foods have longer shelf life, so they are easy to stock and enjoy on-the-go.

With the current pandemic sweeping India, the instant food market is expected to grow further. With restaurants closed, people working-from-home, and hygiene more important than ever before, packaged instant foods offer convenience, variety of flavours and contamination-free quality for consumers.

POPULAR PACKAGED INSTANT FOODS

Packaged instant foods covers a wide gamut of products. Some of the most popular ones include:

Instant noodles

These have become extremely popular across India. Convenience and economic

value have made instant noodlesa household favourite in cities, towns and

villages.

Instant breakfasts

From ready-to-cook savoury oats and porridge to

muesli and cornflakes; from instant idli/dosa batter to instant upma and poha -

Indian retail shelves offer the consumer a range of foods to pick from.

RTE/RTC/RTS foods

Ready-to-eat and ready-to-serve foods include processed meats, chicken products,

curries, parathas, chapatis,and cooked foods like palak-paneer, dal makhani,

chana masala, rice dishes, etc. that consumers just heat and eat.Ready-to-cook

includes cake mixes, pudding mix, gulab-jamun mix, dhokla mix, soup powders,

gravy masalas, etc.

Sweet/Savoury snacks

India loves to snack! And products such as namkeen, mithai, kachori, etc. are

to be found in every Indian home. When packaged well, they become attractive

on-the-go food options.

NICHROME'S INSTANT FOOD PACKAGING

SOLUTIONS

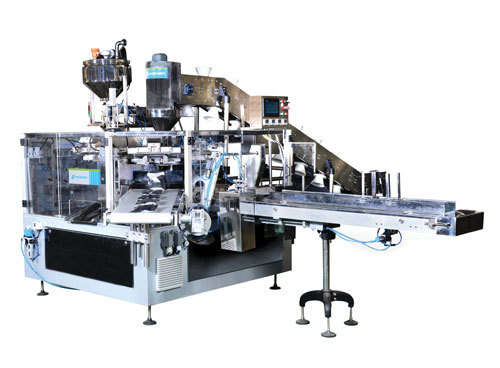

Nichrome is India's leading food packaging machine manufacturer, with expertise built up over four decades in the industry.

Nichrome's efficient R&D and understanding of Indian food products is matched by their cutting-edge technology and manufacturing capabilities.

Whether you want to pack mithai or biryani in airtight, thermoformed trays using MAP technology, vacuum-pack breakfast cereals, noodlesor dry snacks in flexible pouches, or package RTE/RTC foods in eye-catching stand-up packs - Nichrome has a solution for you.

Nichrome's automatic packaging machines for instant foods are all built sturdy and compact. Theyare easy to clean and maintain, and provide fast, accurate and hygienic packaging of the highest global standards. Besides its own Pick-Fill-Seal machine that uses versatile Rotary technology, to conveniently pack a wide variety of ready-to-eat foods, Nichrome offers Athena, thermoformingtray sealing machines from Tecnovac, Italy. Athena is able to seal, pack in a protective atmosphere (vacuum + gas) or with “Skin effect” all types of trays or jars.

The modified atmosphere packaging (MAP) machine extracts oxygen & carbon dioxide from the air of the trays, synchronously filling them with nitrogen or mixed air, to ensure that food does not deteriorate. Then the tray is well sealed. Ready to eat meals packed in modified atmosphere packages are guaranteed to stay fresh for at least 72 hours.

Nichrome also offers a range of HFFS machines for different food products. With their new-gen linear technology, these horizontal form fill seal machines will bring a unique versatility and efficiency to your food packaging operations.

Discuss your instant food packaging requirements with Nichrome. For enterprises big and small, in India and abroad, Nichrome partners to add value through the entire lifecycle. Nichrome studies the customer’s requirements, goals and application challenges to deliver innovative food packaging solutions that will protect the purity of the product, improve time-to-market, and enhance the retail value of the brand.