Currently, India is the largest milk producer in the world. Over the last three decades, India has transformed from a country with acute milk shortages to the world's leading milk producer. In the latest report by IMARC Group titled 'Dairy Industry in India 2021 Edition', the dairy market in India is expected to cross INR 21,971 billion by 2024.

India is also the leading consumer of milk with the dairy industry divided into organised and mostly unorganised sectors.

Despite COVID-19 induced restrictions, the organised sector is projected for a 5-6% growth, as per CRISIL. While consumption is majorly of liquid milk, there is growing demand and consumption of VAPs (value-added products such as lassi, flavoured milk, ice-cream, yoghurts, cheese, ghee, etc.).

All this means that there is a growing need

for systems and infrastructure that augment milk productivity, milk processing

and product quality. With increasing population, higher disposable income,

higher per-capita consumption, larger vegetarian population, demand for

hygiene, etc., the industry has to transition to a more organised market, with

investment in dairy and milk packaging machines.

Nichrome’s connections with India’s dairy

industry go back 45 years. Nichrome pioneered India’s first milk packaging machine in

the 1970s in response to the Government’s call for indigenous, cost-effective

packaging solutions. The first Filpack machine developed by Nichrome was commissioned at

Kurla Dairy, Mumbai where the commercial distribution of milk pouches was started

on 7th March 1977.

Today, Nichrome is amongst the country's top milk packaging machine manufacturers. Nichrome offers a world-class range of milk and dairy packaging machines and systems that enable milk & dairy producers to grow their business with the quality of the product intact. From small dairy farmers to large dairies to multinationals, Nichrome partners with this sector right from consultation and customised solution development to dependable service and support.

NICHROME'S

VFFS FILPACK SERIES

The Filpack Series comprises different automatic packaging machines for filling and packing milk and other dairy products. The range includes:

Filpack Servo 12K: India’s fastest milk pouch packaging machine, packing a record 12,000 pouches per hour.

Filpack Servo 6K: A high-speed, low-wastage milk packaging machine, packing 6,000 pouches per hour.

Both these milk filling machines offer a choice of pouch width options – 100 mm, 125 mm and 150 mm, in sizes of 200 ml, 500 ml and 1000 ml.

The machines have a complete stainless steel structure, with a digital heat control system for maximum accuracy and insulated tanks to maintain product temperature. Recipes can be set and quantity can be changed through the HMI alone and machine automation can be remotely accessed.

Filpack CMD Alpha: This automatic milk packingmachine is built shorter and occupies less floor space. Twin heads mean you can pack two different products at the same time; you can even conduct maintenance on one track while the other is in operation. Filpack CMD Alpha is a popular choice for packaging milk, flavoured milk, lassi, curd.

Filpack CMS 5L: This versatile machine packs both liquids and viscous products with speed and accuracy, in larger 5500ml pouches. Liquids are packed at a speed of 800 pouches/hour, while viscous products are packed at 400 pouches/hour.

A pneumatic filling system ensures better filling consistency while the enclosed SS cabinet and SS 304 product contact parts ensure hygienic, maintenance-friendly operations.

Filpack Servo Universal: This is Nichrome's nextgen solution in dairy products packaging machines. It serves multiple applications in both free-flowing liquid (milk, buttermilk, water, juicy drinks, etc.) and viscous (cream, ghee, mayonnaise, kefir, etc.). Output speed goes up to 5000 packs per hour.

Filpack Servo Universal is also available in a Double Head Combo.

NICHROME'S HFFS MACHINES FOR DAIRY PACKAGING

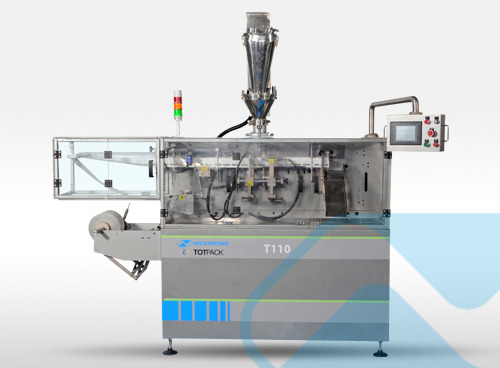

T-Series: This line of horizontal-form-fill-seal (HFFS) machines incorporate the latest linear technology from Europe, and are capable of filling and packing a wide range of products - whether granular, liquid, viscous or powder. For dairy producers who prefer the horizontal format for their operations, the T-Series works well for packaging milk, lassi, buttermilk, flavoured milk, cream, curd, etc.

NICHROME’S

MINI DAIRY PLANT

Nichrome has developed a special, entry-level mini dairy plant for small dairy farmers - to help them achieve their dreams of independent retailing. It is a small milk processing plant, without a boiler, that filters, pasteurises, homogenises and packs milk in 200ml, 500 ml or 1000ml pouches. The milk plant is designed to be compact, energy-efficient and easy to operate for small dairy owners.

CONCLUSION

Nichrome's expertise in dairy products packaging technology is proven and well known - not just in India but in other countries too. Nichrome offers multiple packaging solutions for dairy products such as milk, lassi, buttermilk, curd, cream, ghee, even dairy whitener and milk powder. For dairy powders, check out Nichrome’s Maxima 400/200, Excel 400 Plus Servo Auger, Sprint 250 Plus Servo Auger and Multilane Stickpack.

Nichrome has recently added bottle and tin filling lines that can be adapted for dairy applications.

Across all products and systems, Nichrome's hallmark quality, technology and cost-efficiency are evident. Customers are assured advanced technology, high-quality components and manufacturing, stringent testing - and full installation, training and service support.