Pouch filling machines are becoming increasingly popular for industrial packaging across industries and across the world. Pouches tend to be flexible, lightweight and offer several advantages over traditional packaging such as metal cans or glass bottles.

There are generally two types of pouch filling machines:

Vertical Form Fill Seal (VFFS) and horizontal

form fill seal machines (HFFS), with VFFS being the

preferred option.

Let’s understand the working principles of VFFS

packaging machines:

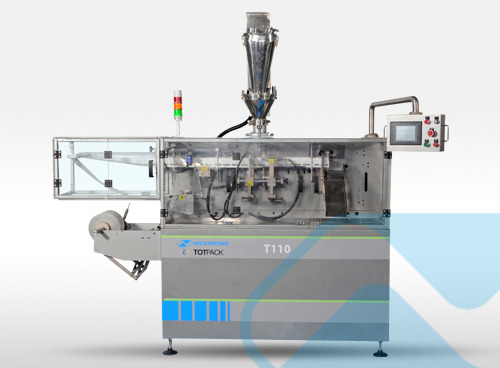

Vertical Form Fill Seal (VFFS) machines are a kind of pouch making and filling machines that have a vertical structure. These machines are mainly used for industrial packaging and processing and provide a more convenient and effective method of automatic packaging which saves time, prevents material wastage and reduces cost.

Let’s look at the main components of VFFS pouch filling machines to understand the working of these machines:

Film Pulling System: This

component of VFFS machines consists of an unwinding roller and tensioner. A

roll of film - generally laminated PE, PET, aluminium foil - is placed on an

unwinding roller - which is usually positioned at the rear of the machine. The

tensioner and servo motors firmly and precisely unwind and pull the film into

the system.

Printer (Optional): This component prints the date, production batch code etc on the film when it passes by the printer.

Pouch Former: The film moves to bag forming once the printing is done. The edges of the film are overlapped to shape the pouch while the top and bottom sealing is done by sealing jaws.

Filling and Sealing

Machine: Filling is carried out by connecting the bagging machine to a

multi-head scale or similar filling machine - such as an auger or volumetric

filler. These two components are synchronized electronically, so that as soon

as the bag is ready, the product is released automatically.

The top of the bag is sealed once the product is dropped into it. The two parts

of the overlapping material are pressed together and welded with heat using

sealing jaws to create a side or centre seal.

Pouch Cut: Once the bag is sealed and filled, it is cut away. The top seal of the first bag becomes the bottom of the next bag ad infinitum. The cut pouch is dropped into a collection system - typically a belt conveyor that carries the pouch to the next step of packaging.

Nichrome’s four decades of experience around the world, innovative R&D, state-of-the-art manufacturing, technology tie-ups with global companies, thousands of successful installations and strong nationwide service network can be matched by only a few pouch filling machine manufacturers. Nichrome’s technology know-how, capabilities and track record are unmatched in the industry. Connect with Nichrome for your pouch filling machine needs.