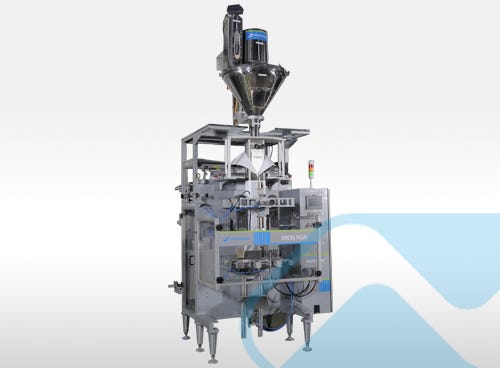

Vertical Form Fill and Seal (VFFS) machines are a boon to modern manufacturing. They combine high production output, consistent reliability and product quality with low manpower requirements and low maintenance costs.

If you’re thinking of getting a VFFS machine for your production process, here’s a check list to help you pick the right one:

1. Space and ergonomics

How will the new VFFS machine fit in your factory? Where will you position it? What is your ceiling height? Can it be easily accessed? Is there space to bring materials in? How & from where will workers engage with the machine? It’s important to study ergonomic constraints and do some work floor planning before acquiring the VFFS machine that suits your set-up the best.

2. Simplicity

Modern VFFS machines are automated, programmable and with ‘date-over-internet’ accessibility. This assures accurate and reliable packaging, and increases ease of operations. But it’s important to look for machines that are simple to integrate, and easy to operate, with minimal maintenance requirements.

3. Price

Machine acquisition is an expensive proposition, involving base price and running costs. That’s why you should take some time before making a decision. Speak to as many vendors as possible, compare each one’s rates, clarify doubts about technology, running costs, training costs, maintenance, etc. — and then choose. Remember, cheapest is not always best, and the highest price does not guarantee satisfaction. Thorough study and evaluation is essential.

4. Versatility

VFFS machines are inherently versatile. Just change the filler, and the same machine can efficiently pack a wide variety of products. But your first priority should be to find the best VFFS machine for your leading product. Evaluate the cost and performance efficiency of a machine ideally suited for your flagship product so you achieve optimal return on investment.

5. Features

VFFS machines come in different models and each of them offers different features. While their main purpose remains the same, their efficiency, output, footprint, etc. varies. Also, there are different levels of automation so depending on your performance targets and your manpower; you can purchase a machine as per your company’s requirement.

6. Assurance & support

A VFFS machine is a big investment, so it makes sense to find a vendor who is reputed and experienced, with sound domain knowledge. Find a vendor who will partner with you, study your product, understand your needs & challenges, discuss total cost-of-ownership, etc. Choose a vendor who can also assure prompt service and support to minimize downtimes, enable up gradations and maximize productivity.

Conclusion

Frankly, selecting the right VFFS machine for your operations can be a confusing task. There are so many aspects to consider, so many pros and cons to weigh. Make the process simpler by talking to a reputed packaging machine manufacturer who will make the time and effort to partner with you and provide comprehensive consultancy and service — both pre-sales and post-sales.

Nichrome is one such reputed packaging solution provider who customizes and integrates packaging solutions to deliver enhanced performance and productivity. To know more, www.nichrome.com

No comments:

Post a Comment