Tuesday, 12 May 2020

Easysnap® single-dose units for liquid and semi-liquid products

Thursday, 7 May 2020

Nichrome: Extending shelf life of fresh food with MAP technology

Modified Atmosphere Packaging (MAP) is the new buzz word in food packaging. MAP is becoming more and more popular for preserving the freshness and extending the storage/shelf life of fresh fruits, vegetables, meats, dairy products, and many more.

What is MAP technology?

According to Wikipedia, “Modified atmosphere is the practice of modifying the composition of the internal atmosphere of a package (commonly food packages, drugs, etc.) in order to improve the shelf life. The need for this technology for food arises from the short shelf life of food products such as meat, fish, poultry, and dairy in the presence of oxygen. In food, oxygen is readily available for lipid oxidation reactions. Oxygen also helps maintain high respiration rates of fresh produce, which contribute to shortened shelf life. From a microbiological aspect, oxygen encourages the growth of aerobic spoilage microorganisms. Therefore, the reduction of oxygen and its replacement with other gases can reduce or delay oxidation reactions and microbiological spoilage.

The modification process generally lowers the amount of oxygen (O2) in the headspace of the package. Oxygen can be replaced with nitrogen (N2), a comparatively inert gas, or carbon dioxide (CO2). A stable atmosphere of gases inside the packaging can be achieved using active techniques, such as gas flushing and compensated vacuum, or passively by designing “breathable” films.’

To package a product in a modified atmosphere requires sophisticated machinery to flush out air from the packaging chamber and replace it with a different gas or precisely defined mixture of gases, then seal the product in the packaging so that only the modified atmosphere surrounds the product and not any other unwanted gas.

Cutting edge technologies have been developed to ensure that the gas mixture is the correct one, and to test that once sealed, the packages contain the right mixture and do not leak.

Nichrome presents Athena, Thermoforming Tray Seal Machine

Tecnovac in Italy is a leading name in the manufacture of packaging machines for food products. Over time it has carved out a name for itself in the packaging world, producing all-round automatic packaging machines for a wide range of products including food, industrial and pharmaceutical products.

Nichrome, India’s leading packaging machine manufacturer andintegrated packaging solutions provider,has collaborated to bring Tecnovac’s highly successful Athena Automatic Tray Sealer to India. Athena is capable of packaging food in modified atmosphere, any combination of compatible trays and top film studied for packaging chopped vegetables & fruits, raw& processed meats, fish, frozen food, Indian mithai, namkeens, and ready-to-eat meals such as biryani. Using pre-formed trays, Athena is able to seal, pack in a protective atmosphere (vacuum + gas) or with ‘skin effect’ all types of trays or jars. Due to its strong stainless steel structure and easy maintenance, Athena is ideal for use in small and medium sized companies. With these features and its output speed of up to 60 trays per minute, Athena should find easy acceptance among India’s ready-to-eat food manufacturers.

MAP, in the time of the pandemic

In the current global situation, Athena offers a win-win proposition for manufacturers of food items and consumers. Especially in India, where snacks, namkeens and mithai are a much-loved part of life, Athena’s MAP technology will ensure that the items are packed safely, untouched by human hands – thereby raising hygiene levels that all consumers are concerned about. Manufacturers can continue production and sale; consumers can enjoy the mithai and snacks they crave with safety and cleanliness.

For further details, and more expert food packaging solutions, talk to Nichrome.

Wednesday, 12 December 2018

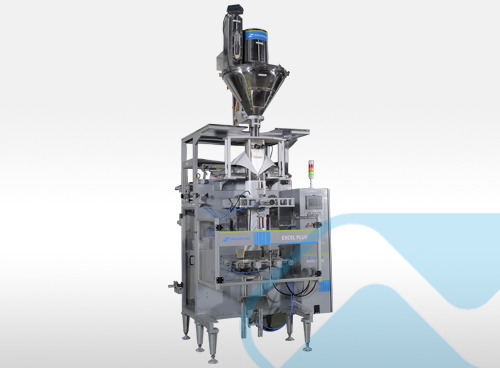

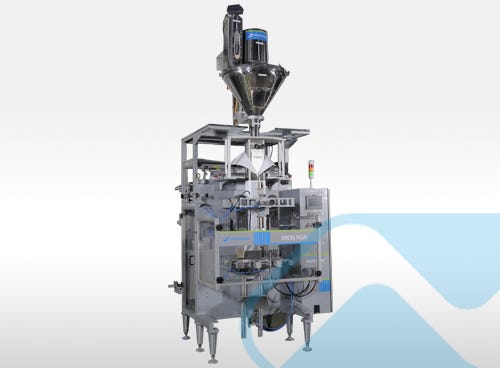

How/Checklist to Pick the Right VFFS Packaging Machine

Wednesday, 21 November 2018

Nichrome Packaging solutions for new application challenges

Nichrome’s true strength lies in partnering with customers through the complete lifecycle, offering customer-centric and application-specific solutions, backed by dependable service and support. For enterprises big and small, for applications existing and emerging, Nichrome aims to transform productivity with its pioneering innovation, extensive domain knowledge and manufacturing capabilities.

|

| Find applications available for packaging services |

In recent times, Nichrome has worked closely with clients to design and build innovative packaging solutions for a wide variety of products. From idli batter and onion flakes to smethana, kehfir and bakery shortening; synthetic resin and ‘neel’ for clothes to handwash powder – Nichrome has developed packaging solutions that fulfill industry needs and meet application challenges.

While moving to the next level of engineering for application-specific solutions, Nichrome is also proving itself to be a competent provider of integrated packaging solutions. For Food, Pharma and other applications, Nichrome is the single source for integrated packaging solutions divided under three broad units: Packaging Machines, Packaging Systems and Filling Systems. In each, with strong R&D, Nichrome partners with enterprises of all scales to innovate solutions that address real needs, and provide comprehensive expertise that creates value through the complete lifecycle.

www.nichrome.com

Friday, 26 October 2018

Stimulating solutions for coffee packaging.