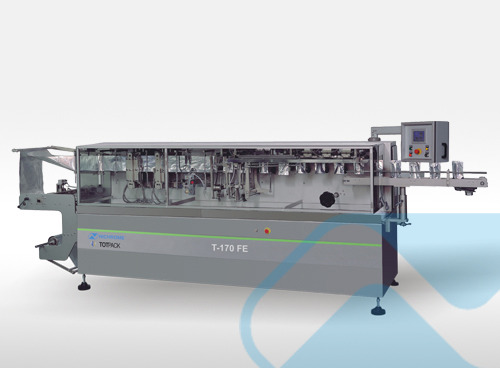

Automatic Packaging Machines

|

| 5 Reasons To Automate Your Packaging Line |

Whether you are an established manufacturing business or a young and growing one, you want to be an efficient and productive enterprise. You want to be a company in tune with the times, meeting and exceeding your consumer’s expectations, growing your profits as you build a stronger brand.

Packaging plays a crucial role in your business, and

adopting the latest technology for it is essential to build the competitive

edge. Manufacturers the world over have adopted automated packaging systems

such as VFFS packaging machines and HFFS

packaging machines. Such flexible

packaging machines are enabling manufacturers to meet their packaging goals

and increase profitability.

Let’s consider some of the reasons to invest in automated packaging systems for your

business.

You can't cater to

growing demand and expanding markets

The demand for your product is increasing. You want to

venture into new markets and territories. Your overworked employees and old

packaging equipment just cannot keep up. Before you lose business to

competitors who move faster than you, or you have to give up on your ambitious

growth plans - think automated packaging line. It'll help you respond quickly

to increase in demand and take the pressure off your staff.

You can't take on new packaging formats & sizes

Consumer packaging calls for varied package sizes and

formats. Competition demands you have more customised SKUs as a point of

differentiation and to fulfill changing consumer needs.

Today's automated packaging machines

are built for versatility so they deliver better ROI.

You can't handle

modern packaging materials

In flexible packaging, there is constant innovation in the

film - to minimise environmental impact and better protect & preserve the

product. Old packaging systems

just don't have the features and capabilities to handle the new materials or

the sealing pressures and precision required.

The cost of

labour, wastage and downtime is killing you

As harsh as it sounds, human resources are expensive to

employ. They can be slow, miss working days, and make mistakes. Human error and

other reasons can cause a ton of waste. Waste of product from overfilling bags

or leaks & spills, inefficient use of shop floor space, waste of time since

the process takes much longer, and frequent downtime due to breakdowns or

faults.

The world demands

accuracy & standardisation

The contemporary consumer is demanding. They expect their

money's worth. Discrepancies in quantity, seal quality, pouch look & feel -

such irregularities can have a negative impact on your brand and your sales.

If such problems ail your business, it’s time to invest in

modern packaging systems that will

help you overcome them. Sure, such an investment can be expensive but in

today's world, they are simply the better choice. Better machines will give

better performance and thereby, better profits.

Still unsure if you can make the change? Nichrome can help.

As India's leading integrated packaging solutions

provider, Nichrome partners with you to understand your needs and limitations,

and develop the customised solution for you.

Nichrome's primary

packaging machines in VFFS and HFFS

formats are sturdy, durable performers with speed, accuracy and

cost-efficiency built-in. They offer unmatched versatility - so you can pack a

variety of solid, liquid & viscous products in a range of pouch formats

with the same machine.

Nichrome also provides secondary packaging and tertiary

packaging systems that can be integrated for a smooth and seamless packaging line. Nichrome also has

expertise for turnkey project design and can custom-design a complete automated

and integrated packaging line for you.