India's vegetable oil consumption is growing. As per the

"India Edible Oil Market 2019-2025" report by ResearchAndMarkets.com,

the India edible oil market to expected to witness a CAGR of 8.75% by Revenue

and 9.88% by volume during the forecast years of 2019-2025.

Growing incomes, urbanisation, changing food habits are key

drivers for consumption growth. Palm oil, soya oil and sunflower oil are

expected to penetrate regional markets further in the future. There is a marked

shift from loose oil to branded, packaged

oil, as changing lifestyles and growing awareness of hygiene and quality aspects

impact buying behaviour. Furthermore, in packaged oil, the preferred consumer

units are 1L and 5L, while commercial users such as hotels & restaurants go

for bulk packs in 15L tins.

Pouches are growing in popularity around the world as a

preferred retail packaging format.

It is a highly convenient, light-weight and portable package that enables

companies to offer their product in a range of customer-friendly sizes - from

as small as 50 ml samples to larger 1L and 2L packs. Pouch packaging offers more advantages:

Protection:

Flexible pouches preserve the freshness and taste, protecting the contents from

contamination.

Portability:

being compact and light-weight, they can be carried and transported easily, and

require less secondary packaging than

rigid packs. They also optimise shelf space.

Retail value:

Pouches can be customised for individual brands in specific sizes for different

markets. They can be branded for visibility and differentiation on retail

shelves.

Reach: The

quality, safety and easy transportability of pouches enable great ‘last mile’

reach, helping marketers to reach wider rural and regional markets.

Economy:

Flexible pouches are more cost-effective compared to alternative packaging

materials such as PET bottles, tins, Tetrapak and glass.

Sustainability:

Pouch materials release minimal emissions in production and are partially

recyclable.

Nichrome solutions

for Oil

Packaging

For every oil manufacturer, big or small, hygiene, accuracy

and leakage-free sealing are crucial. With four decades of experience in the flexible packaging industry, and 7000+

installations across India and the world, Nichrome can proudly claim to be the Oil

packaging machine manufacturer who delivers outstanding single-source

convenience and infinite possibilities in integrated, automated packaging solutions.

With a wide selection of both HFFS and VFFS innovative packaging solutions,

Nichrome ensures it has a solution for every need and budget. Nichrome’s VFFS

packaging machines are high speed, accurate and hygienic, with the

capability of packing two different products and quantities at the same time.

Nichrome’s Filpack Servo SMD and Sprint 250 Visco are

engineered for all oil and related applications including ghee packing and for other viscous products such as vanaspati and

fresh cream. Their CSPP pouch and 3-side seal pouch are the perfect solutions

for all cooking oil packing. The

output speed is between 80 and 85 packs per minute.

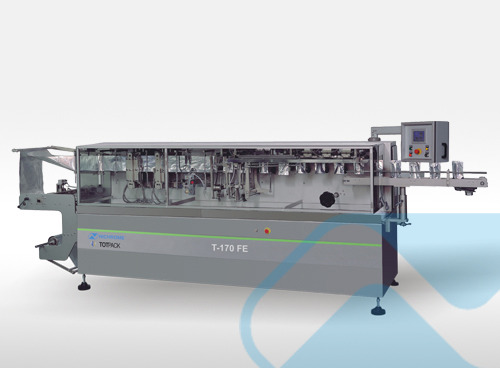

Nichrome’s HFFS oil

pouch filling machines from Nichrome can pack between 5 and 250 cubic

centimetres in the Simplex version and between 5 and 90 cubic centimeters in

the higher-output Duplex mode. The rated output for the simplex version is 100

packs per minute while the duplex version delivers 200 packs per minute. The HFFS

pouch filling machine utilizes a piston filler for viscous

applications. Alternative pouch formats include the four-side seal and zipper

pouch formats as well as a contour/profile pouch format. The pouches can be

rolled out by the edible oil filling

machine either one by one or as a perforated chain of pouches. The

packaging materials for the HFFS machines are heat sealable laminates like

PET/PE, Paper/Alu-foil/PE or co-extruded films.

Nichrome also offers secondary

and tertiary packaging solutions for oil

pouch packaging. So whether you are looking for a high-performance, high-speed oil packaging machine or a

complete, integrated packaging solution, consult

Nichrome. Their domain expertise and decades of experience will ensure you get

the most relevant, cost-efficient and reliable automated packaging solution for your operations.