Sachets

for shampoo are now a common phenomenon. It started years ago when rural

consumers, attracted by the low unit price, lapped up the idea. Then,

travelling urban consumers too discovered the convenience of these sachets -

and now the format is being extended to other FMCG products like toothpaste,

lotions, ketchup, etc.

Today,

cooking oil manufacturers are exploring the advantages of the small pack to

target different audiences. The Dalda brand offers itself in mini packs, priced

really low, to appeal to the mass market.

The

target segments include students staying alone and daily wage earners who

typically buy one or two days' worth of oil consumption at a time - either

because of the affordable pricing or because they don't have the facility to

store larger quantities.

Cookingoil packaging in small sachets also targets a more premium audience - the

hospitality sector. Today olive oil and oil-based salad dressings are packed in

single-serve sachets and used by take-away eateries, restaurants, hotels,

airlines, etc.

For

edible oil manufacturers interested in such target audiences, Nichrome offers cooking oil packing machines with advanced technology. These

include:

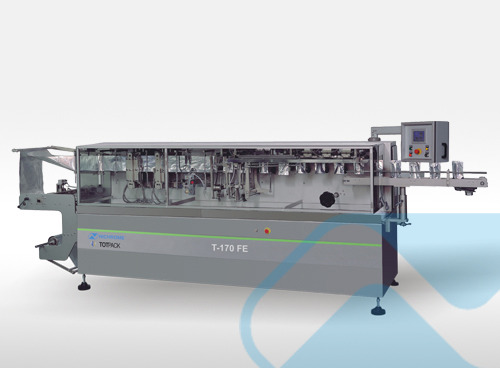

Multilane Stickpack with Multi-Piston Filler

Nichrome's

Multilane Stickpack with Multi-Piston Filler is a stick pack pouch packaging

machine especially innovated for packing liquids and viscous products in

convenient, single-serve stick packs.

For

packaging liquids and viscous products such as edible oil, honey, ketchup,

mayonnaise, mustard paste, jam, shampoo, etc., Nichrome's STICKPACK offers a

stainless steel structure, pneumatically operated piston filler and

longitudinal & cross-sealing jaw assemblies suitable for laminates. A CE

certified PLC controller makes it easy to operate.

This

oil pouch packing machine has

up to 6 lanes and packs quantities of 5 to 30 ml in convenient stick packs.

PV-215

These

are high speed, flexible, PLC-controlled machines. For practically every

application in Pharma, Personal Care, Cosmetics, Healthcare and Food

industries, PV-215’s intermittent motion technology ensures efficient sealing

and a bagger speed of up to 1000 bags/min.

PV-215

is an extremely flexible oil packaging machine that can quickly accommodate any attachments/additional

features at any stage due to its shaft-mounted modular concept. It also offers

wrinkle-free sealing and user-friendly web tracking.

The

PV-215 offers a variety of pouch formats: 4 side seal, 4 side seal with notch,

contour pack, contour pack with V notch, and twin pouches. It packs quantities

of 5 gm and more, at a bagger speed of 1000 pouches per minute.

Conclusion

When

it comes to oil packaging machines, few can match the

range and expertise of Nichrome India, pioneer of flexible packaging in India,

and leading oil packing machine manufacturer. Nichrome has a range of VFFS

and HFFS cooking oil packaging machines to suit diverse

needs, and even offers project capabilities to set up complete oil packaging

plants from concept to commissioning.

Since 1977, Nichrome has been at the forefront of

next-generation packaging technologies; a brand trusted for its rich legacy of

pioneering innovation, extensive domain knowledge and manufacturing competency

in packaging systems.

For enterprises big and small, for applications

existing and emerging, Nichrome offers infinite possibilities in integrated,

automated packaging solutions - as they partner with customers through the

complete lifecycle, offering application-specific solutions, backed by

dependable service and support.