Across industries around the globe, automatic packaging

machines have been on

an exponential growth path. The major reasons for this are their speed,

accessibility and ease of use as well as the superior appeal of the packaging.

The filling system is a critical

element of both vertical form-fill-seal

machines and horizontal

form-fill-seal machines. This is a component that is responsible for the

accurate measurement and release of the specified quantity of the product that

is to be filled in each pouch. The choice of filler is made on the basis of the

product that has to be packed. Some common filling systems include the cup

filler, auger filler, linear weigh filler, combination weigh filler, piston

filler among others.

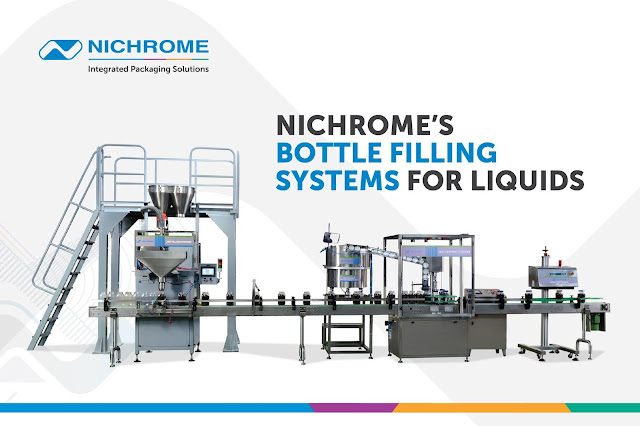

Being the leading provider of integrated

packaging solutions, and a renowned packaging

machine manufacturer, Nichrome brings to you a plethora of filling systems for diverse

applications in the food, pharma and non-food segments. The filling systems are

selected on the basis of the product that needs to be packed. Whether it is liquid packaging, grain packaging, snack

packaging, oil packaging, sugar packaging or ready-to-eat food packaging - different products will need

different kinds of filling systems.

There are primarily two basic criteria used by packagers use to determine the

right filling system for their particular application:

Criteria for Choosing a Filler

Level of automation: Filling systems are designed to be integrated with automated packaging systems. They can also be configured to operate as single, semi-automatic machines, for eg, by integrating the filler with capping machinery.

To pinpoint the

level of automation required for your filling system, it is important to

determine the packaging rate and capacity you will require. In case of higher

production levels, it may be necessary to use something like an eight-headed automatic filling machine with the

option of adding additional heads in the future.

Filling process: The filling process

is determined by the distinctive traits of the packaged product. A milk filling machine and a powder filling machine will need

different configurations and designs. Same goes for an automatic sugar filling machine and edible oil filling machine - they will all need different kinds of

fillers to operate.

For instance, gravity fillers are apt for thin and free-flowing products.

Denser, viscous products cannot work just on the basis of gravity, and hence a

piston filler or pump filling machine needs to be used instead.

Nichrome Range of Filling Systems

Nichrome brings

with it an extensive range of filling systems

for varied and diverse applications. Nichrome’s filling systems come in

different filling capacities and have built-in safety features. They can also

be easily integrated into existing packaging setups and offer greater

efficiency, speed and versatility.

Let’s take a look at Nichrome’s range of innovative filling systems:

Intelweigh Multihead Weigher:

Highlights:

● 10 weigh heads

● Combination volume of 3000 cc

● Ideal for granular products like tea,

sugar, rice, pulses, snacks

● 1.3 L bucket volume

● 0.2 to 2 gm accuracy

● 10 gm to 1000 gm weighing range

● Speed of 70 dumps per minute

● Product contact parts made of SS 304

● 7-inch touchscreen display

● Stepper motor to open and close

buckets

● Load cell weight method.

Highlights:

● Aesthetically improved machine

● Safe for users

● Ideal for filling solid products like

seeds, whole spices, grocery products, Indian namkeen etc

● Accuracy % sd: 0.5% / 0.2%

● Weighing range: 50 gm to 2 kg and 500

gm to 5 kg

● 7-inch touchscreen display

● Air consumption of 0.15 CFM at 6 bar

● Connected load/head of 0.25 kW

● In-built safety doors and guards with

machine interlock

● Wide range of filling capacities are

available

Easyfill Servo Auger:

Highlights:

● Accurate, fast and efficient

performance

● Available in different finishes -

buffed, Teflon coated, Nedox coating

● Split hopper for easy cleaning and

ease of changeover

● Apt for packaging powders like spices,

flours, milk powder, nutraceuticals et al

● Filling capacity: 5 cc to 2000 cc

● Servo-driven auger mechanism

● SS 304 or SS316 contact parts as per

product requirements

● PTFE/Food Grade silicon rubber gaskets

● Hygienic filler construction

● MS powder-coated structure

● Hopper with inner buffing and outer

matt finish

● Easy cleaning

Summary

Filling systems are critical components of packaging machines and play

an important role in their efficient operation. Nichrome’s filling systems are

manufactured using cutting-edge technology and feature a user-friendly design

for a diverse range of applications.

Nichrome is

participating in the ANUTEC Expo -

India’s largest international fair for food and drink technology - being

organized between 14th-16th September,

2022 at the Bombay Exhibition Centre

in Mumbai. Do visit us at Stall No F49 to see our range of

products.

Visit www.nichrome.com

to find out more!