Nichrome is India’s leading integrated packaging solutions provider, with over four decades of expertise in their domain. Nichrome constantly assesses evolving market needs and develops automatic packaging solutions that are suitable, efficient and cost-effective.

With India’s snack market growing in leaps and bounds, traditional namkeens are in demand - as they are all-time favourites. However, considerations regarding hygiene and comfort have forced namkeen makers to adopt the latest trends in packaging to retain their spots on retail shelves.

Every automatic packaging machine

from Nichrome comes with the latest technology, with the focus on ensuring the

freshness, crispness and shape of the snacks.

The VFFS namkeen packaging machine range from Nichrome includes:

Wing 200 E-line Snack Pack

The Wing 200 is an exclusive packaging solution

from Nichrome designed for startups and small-medium enterprises. It comes with

Nichrome’s extensive expertise and its reliable technology in a compact,

affordable design that is configured to fit relatively modest space, budget and

performance requirements.

It has the capacity to pack CSPP pouches at a rate of 80 pouches/min.

Excel Vertipack 320

Excel Vertipack 320 comes with the assurance of robust performance and

unmatched versatility with its sturdy design, online check weigher and metal

detector, compatibility with multiple fillers, and an abundance of other

features.

Sprint 250 Snackpack

The Sprint 250 Snackpack was designed particularly for the

snacks and namkeen industry and offers quick and easy tool-less changeover of

parts resulting in minimum product fall height.

The Sprint 250 Snackpack’s construction is HACCP & GMP compatible and can

pack a wide variety of namkeens, snacks and related food items in various pouch

formats such as Gusset with D-cut, Gusset and CSPP. It has a perforation system

that allows for the production of chains of small pouches. It has an output

speed of 150 packs/min.

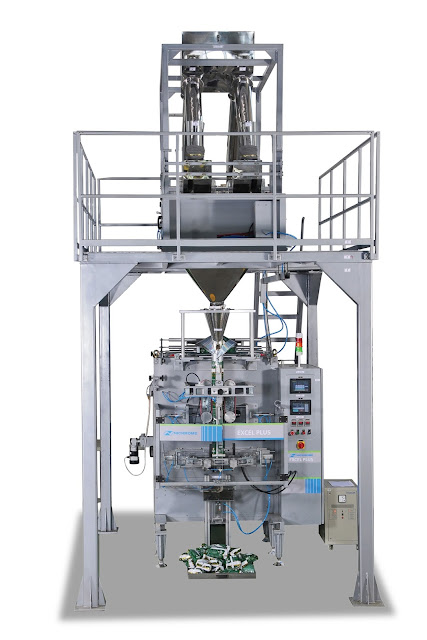

Excel 400 Plus Multihead Weigher

Coming with the added advantage of automation, the Excel Plus

series is equipped with CE marked PLC controller and touchscreen. Some

significant elements of this series are static charge eliminators, print mark

scanners, servo motor driven bag length control system and adjustable

cross-sealing jaws for the best performance. It can be easily integrated into

upstream or downstream systems as well.

This series is compatible with a range of fillers which makes it a genuinely

versatile solution for snacks, powders grains, granules, snacks etc. It can

pack in a variety of pouch formats such as Pentaseal, 4 line seal, CSPP, Gusset

and Pentaseal with D cut.

Sprint 250 Plus Multihead

Weigher

The Sprint 250 Plus from Nichrome offers accuracy and efficiency for the flexible packaging of a diverse range of snacks, grains and powders and can package pouch quantities up to 2 Kgs with an output speed of up to 150 packs/min. Being an automated packaging machine, the Sprint 250 Plus comes with CE marked PLC and a touchscreen HMI. The servo motor driven sealing system is very effective at sealing while maintaining pressure levels. It offers a perforation system to deliver a chain of small pouches and is programmed to pull the exact length of film required for packaging.

Nichrome offerings also include a range of HFFS Namkeen packaging machines with the latest linear technology from Europe. These machines are quite versatile and can be deployed to pack a wide range of powders, grains, snacks, liquids and viscous products with a range of fillers. This series offers a variety of pouch formats with superior aesthetics.

The HFFS machines have a touchscreen interface and are based on PLCs. With a compact and versatile design, this series offers both single and perforated chain of pouches with quick and easy changeovers. Duplex modules are optional for higher output requirements.

Conclusion

If you’re a manufacturer of namkeens and other snacks and want to improve your packaging for a wider market, Nichrome can be considered your ideal packaging partner. Nichrome’s integrated packaging solutions are automated with CE marked PLC controllers and a touchscreen HMI for ease of operation and control. These packaging machines can be conveniently integrated into upstream/downstream systems and can be used for a wide range of applications as a result of their compatibility with multiple fillers and quick, tool-less changeover.