Automatic liquid filling machines and

end-to-end production lines are helping make liquid packaging more accurate, fast and hygienic across a

wide range of industries. Producers in the food and beverages, pharmaceutical,

chemicals and cosmetics industries have come to realise that automated filling machines and automatic

packaging machines have the capacity for much higher production speeds than

manual filling. Even in the case of plastic or glass bottle filling, automated

machines are more reliable in terms of accuracy, hygiene and output.

Considerations for Liquid Packaging

Even before the

product hits the shelves, packaging and processing facilities must ensure that

the product remains free of contaminants and possible spoilage before

consumption.

While the packaging design is crucial for keeping products safe from

contamination and spoilage, liquid products need to be protected prior to the

packaging process.

Effective packaging systems integration needs to be

utilized to ensure that the products remain safe at all times during the

packaging process. In the case of liquid packaging lines, this includes using

dependable liquid filling machines and related packaging

equipment specifically designed to handle the product.

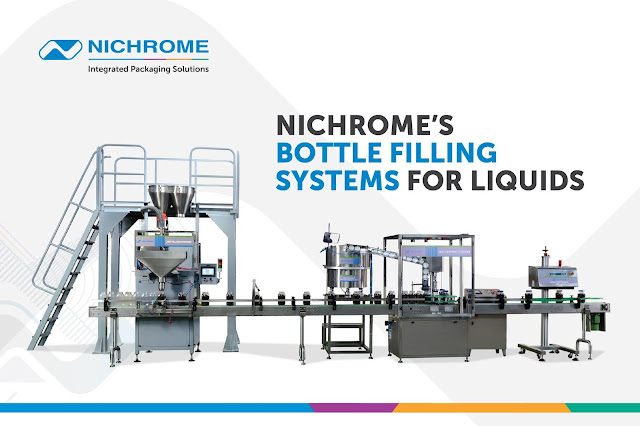

Nichrome displays its superior capabilities in Bottle Filling Systems for

liquids.

Nichrome’s Liquid Packaging Solutions

Liquid packaging was the first technology developed

by Nichrome way back in 1977. Nichrome answered the government’s call for

cost-effective indigenous milk packaging by

manufacturing India’s first indigenous milk pouch packaging machine.

Nichrome’s

diverse range of liquid packaging machines is suited to

packaging a wide variety of liquids. Nichrome has innovative packaging

solutions for liquids ranging from free flow liquids, to highly viscous.

Nichrome boasts of decades of experience in handling the different

characteristics of different liquids: foam generating liquids, liquids with

lumpy particles, liquids that need nitrogen flushing, liquids that require

constant temperature, flammable liquids etc. Nichrome has the capacity to

customise solutions for client-specific requirements.

Nichrome’s Bottle Filling Line for Liquids

Nichrome’s automatic bottle filling system is an integrated packaging solution

that can pack liquids in SKUs from 100ml to 20ltrs.

Some of the applications of this automated bottle filling system include

a diverse range of food and beverage liquids such as flavoured milk, water and

buttermilk, soft drinks, energy drinks; non-food liquids such as perfumes,

shampoo, handwash oil; viscous products such as ghee, ketchup, chocolate sauce

et al.

Nichrome’s

bottle filling line is an efficient integrated system for bottle filling and

packaging. The components of this system include:

● Turntable

● UV sterilisation chamber

● Automatic liquid filling machine

● Cap feeding elevator

● Rotary capping machine

● Induction sealer

● Labelling machine

● Date & batch coding system

● Packing table

Key Features of Nichrome’s Bottle Filling Line for

Liquids

● “No Bottle, No Filling” safety device

which prevents spillage or drippage of liquids if there is no bottle in the

line.

● Auto cap placing, pressing and

screwing feature available which effectively automates the bottling process.

● Glass, HDPE, PP bottle and Metal Tin

friendly line, so that a variety of container/bottle types can be filled.

● Machine construction available in

SS304, SS316 and M.S painted.

● PLC controlled line for precision and

accuracy.

● Fast changeover design for different

bottle sizes for quick changeover.

● Digital LCD touchscreen display and

settings for easy control and operation.

● Safety enclosures with interlocks for

rotary parts to prevent accidents.

● Various bottle sterilization and

cleaning options available for specific highly sensitive liquid packaging.

● Versatile SKU packing range without

the need to change parts.

● Fast cut off option to achieve

accuracy and speed.

● Completely drip-free filling to avoid

wastage and spillage.

Conclusion

Nichrome is

India’s leading automatic filling

machine manufacturer, and the pioneer in Milk pouch packing machines in India.

Since

Nichrome’s development of India’s first indigenous milk

packaging machine

in 1977, it has been at the cutting edge of next-generation packaging

technologies. It has been a brand trusted for its rich legacy of groundbreaking

innovation, expansive domain knowledge and manufacturing prowess in packaging

systems.

As an

innovative packaging

machine manufacturer, Nichrome has always had a strong belief in partnering with customers in

order to understand their product and the challenges therewith, and providing

value in every interaction. Nichrome’s impressive portfolio of advanced

packaging solutions and global presence has been built on the platform of its

strong in-house R&D and manufacturing capabilities.

Connect with Nichrome for your liquid packaging machine needs today!