Nichrome is India’s leading packaging machine manufacturer, generating automated packaging machines that equip you with the latest, safest and most integrated packaging solutions.

Based in Pune, Nichrome has its presence in 45 plus countries with more than 10,000 installations. Nichrome started with developing India’s first milk packaging machine in 1977 and continued its journey to today produce packaging machines that cater to the food industry, pharmaceutical industry and non-food industry.

Providing integrated packaging machines in India, Nichrome is proud to announce that it will once again showcase India and the brand at the Gulfood Manufacturing 2022.

GULFOOD MANUFACTURING 2022: world’s leading event for food and beverage

Initiated in 2014, the Gulfood Manufacturing is one of the world’s leading events for food and beverage. The event is held every year to bring together world’s leading food and beverage authorities, manufacturing companies, supply chain entities and big and influential names of the industry and share knowledge, experience and build meaningful relationships with each other.

After a successful 2021 edition, Gulfood Manufacturing returns with its 2022 edition which will be active for three days starting from 8th November to 11th November.

The 2022 edition promises to cater to you with intellectual seminars, informative and interactive showrooms and great network building opportunities. The leading food manufacturing companies will grab the floor to showcase their advanced, improved and innovative production, processing and packaging technologies.

THe event will also witness the annual Gulfood Manufacturing Industry Excellence Awards that will nominate companies across seven categories and officially announce the winners both live and online.

HOW NICHROME’S PACKAGING SOLUTIONS MAKES IT THE MOST RELIABLE PACKAGING MACHINE MANUFACTURERS IN INDIA

Nichrome has more than 40 years of experience in the industry which has given the company a potential strong base. With a sturdy R&D and extensive domain knowledge, Nichrome deals with enterprises of all scales and sizes to provide them with integrated solutions that address real needs.

1. PRODUCT HANDLING: Product handling is an integral and most basic yet important part of a food packaging machine. Nichrome gives you the most reliable conveying packaging system that gives you access to screw conveying, vacuum conveying, belt and bucket conveying. It also gives you reliable product storage which is offered in the form of storage silos, jumbo bags and jumbo bag dispensing. The product processing involves cleaning, grading, mixing and distribution.

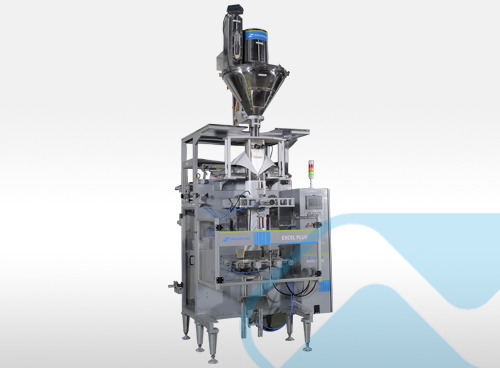

2. PRIMARY PACKAGING: Primary packaging is the primary part of packaging and should have a consistent quality packaging. For projects big and small, for Food, Pharma & Non-food applications Nichrome partners through the complete life cycle, innovating and integrating solutions that elevate productivity through performance. Nichrome offers proven expertise and single-point convenience right from the beginning of the product packaging. Nichrome’s product packaging system gives you access to various filling packaging systems:

- BOTTLE FILLING LINE SYSTEM: Nichrome manufactures the most reliable bottle filling machines that can cater product packaging of liquids, powders, granules & solids. The applications of bottle filling line systems range from milk, cleaning products, protein powder, spice powders, seasonings, pharma powders to pulses, grains, sugar, tea, tablets, dry fruits, soya chunks & whole spices. You can simply just change the filler and use the filling line for any liquid, powder and solid application. The PLC-controlled system is fitted with a unique ‘no bottle no filling’ safety device, and safety enclosures with interlocks for rotary parts. It works well for glass, HDPE and PP bottles and offers fast changeover for different bottle sizes

- JAR FILLING LINE SYSTEM: Nichrome is a versatile jar filling machine manufacturer that provides you with an integrated packaging system that is largely used to fill solids like tea, small biscuits, nutraceutical powders, health drinks, wrapped candies, etc. It also holds viscous products like ghee, peanut butter, mayonnaise, chyawanprash, etc. We also provide the complete solution for all kinds of bottle filling, foil sealing, capping, labeling and batch coding requirements. The PLC-controlled system is installed with a unique ‘no bottle no filling’ safety device, and safety enclosures with interlocks for rotary parts which avoids any wastage and error during product packaging. It works well for glass, HDPE and PP bottles and offers fast changeover for different Jar sizes.

- TIN FILLING LINE SYSTEM: Nichrome’s tin packaging machine is a robust, low-maintenance packaging machine made for meticulous and competent performance.The PLC-controlled line has a digital LCD touch screen displaying settings, and safety enclosures with interlocks for rotary parts. It also benefits you with machine construction which is available in SS3014, SS316 and MS painted material. You also access yourself with various tin sterilization and cleaning options for hygienic packaging solutions.

- BULK BAG FILLING LINE SYSTEM: The newly introduced bulk bag machine from Nichrome is designed for packing large bags ranging from 5 kgs to 50 kgs. The bags could be HDPE woven, PP, paper or valve type. It is ideally suited for products such as rice, sugar, grains, pulses, flour, cake mix, cement and agro-chemical granules. The PLC-controlled machine delivers you with a speeding output rate of up to 20 bags per minute, and has a special ‘no bag no filling’ safety device installed which helps with minimum wastage and maximum usage. Other features of the bulk bag filling system includes auto bag clamping, bulk and dribble feed, and bag tilting & alignment attachment with option of bag stitching or band sealing which again helps you avoid any wastage and save more time.

3. SECONDARY PACKAGING: As the name suggests secondary packaging is the second layer of packaging which gives additional protection. The secondary packaging also helps you bring numerous small products together which increases the safety during heavy transportation. It is also referred to as overwrapping or outer packaging.

- FLOW WRAP MACHINE: Nichrome has designed the Flexiwrap 700 — flow wrap machine that has automated flow wrapping along with manual product feeding into specialized conveyors. You can have a quality pouch wrap packaging with a wide range of layflat widths. Nichrome’s flow wrap machine gives you access to a lot of additional features like Intermittent motion, quick and friendly changeover for forming different size parts, PLC program to store different recipe for changeovers, center seal and center conveyor driven by servo motor, side sealing facility, lamination compatibility, speed up to 60 pouches per minute.

- AUTOMATIC POUCH COLLATION & FLOW WRAPPING MACHINE: The new secondary flow wrap packaging machine — Flexiwrap ST will allow you to integrate existing form fill seal/FFS machine to bundle the individual pouches into distributor packs or retail ready packs. The advanced technology of the Flexiwrap ST machine comes with automatic counting, automatic stacking and automatic flow wrapping. It also has unique features like high speed stacking, easy changeover, auto pouch stacking as per desired matrix, single operator driven system, PLC controlled line, digital LCD touch screen displaying & setting and safety enclosures with interlocks for rotary parts.

4. END LINE PACKAGING: End line packaging solution also termed as ‘tertiary packaging. Nichrome’s end line packaging offers palletizing solutions for both bags and cases. To make your packaging more efficient and consistent we also offer customized solutions which includes automatic pallet dispensing, collation using pack automatic pick and place (robotic/gantry), palletizer (robotic/gantry), multiple line configuration integration and stretch wrapping.

CONCLUSION: Nichrome over the years has made itself emerge as India’s leading machine manufacturers who keep a vision to become the most integrated packaging solution provider locally as well as globally bringing progress to the customers, employees and stakeholders with constant innovation and improvement. Nichrome is currently serving in more than 45 countries and is successful in providing 10,000 plus installations worldwide.

Nichrome has been serving big as well as small segment businesses and helping them grow and advance themselves with latest and automated packaging solutions.

With the same vision, Nichrome will showcase in the 2022 Gulfood Manufacturing event at Dubai which will have more than 150 representative countries with 1500 plus exhibitors and over 26000 trade visitors. The massive event will be held in Dubai at the Dubai World Trade Centre from 8th November to 11th November.

Nichrome is a versatile manufacturer of the following packaging machines and solutions for your one stop packaging solutions — Bottle Filling Line, flow wrap machine, powder filling machine, automatic bottle filling machine, cartoning machine, shrink wrapping machine for bottles, carton box packing machine, tin packing machine, can seamer machine, shrink wrapping machine manufacturer, horizontal flow wrap machine, jar filling machine manufacturers, bulk bag filling machine, case packer manufacturers india, powder bottle filling machine, automatic case erector, auto case erector, automatic carton box packing machine, tin filling machine, oil tin filling machine and tin can filling and sealing machine.