Packaging is no longer limited to the pouch, box, strip or any other material that holds and protects the product. It’s an entire system of preparing products for safe, efficient and cost-effective movement throughout the supply chain.

Industry is now aware that packaging is not just the work of designers and marketing departments who focus on brand recognition and driving sales. Their emphasis is on developing packaging that grabs attention on crowded retail shelves.

With attention on driving sales and brand recognition, not much emphasis is placed on or trailer utilization of the package itself.

Packaging plays a crucial role in supply chain management. It affects the physical distribution of the package. Logistics demands packages that can be easily handled throughout all processes and by the consumer. Packaging also affects production, which prefers one size of packaging for all products to minimize time, material, and labor costs.

Package optimization makes the difference.

Package optimization is an activity that seeks to make the product’s packaging more supply chain friendly. By making small changes, packaging can be made more ergonomically and sustainable, saving time, material and money that can make a big difference to the company’s supply chain. This in turn, leads to maximized return on investment.

Here are three basic ways to optimize your packaging:

1.Choose the right materials: It’s important to make smart decisions about the proper primary, secondary and tertiary packaging to help your product and its packaging navigate the different stages and environments it will travel.

Materials that are expensive or difficult to use could add time and money to your supply chain. The good news is, you can often reduce or change your packaging materials without compromising the quality of your product or the perception of your brand.

2.Think sustainability: Package optimisation is an opportunity to go green and promote sustainable business practices. You can find ways to use less material and/or find materials with reduced carbon footprint. This will help you save money and the environment — while enhancing your company’s image as an environmentally responsible corporate citizen.

3. Optimise shipment costs: When it comes to shipment from factory to retail shelf or consumer, the size and weight of your boxes impacts your logistics costs. Optimising your product package ensures you optimize the space and weight occupied in transportation and storage, so you can transport more products — saving both time and shipping costs.

How Nichrome helped saved millions with packaging optimisation

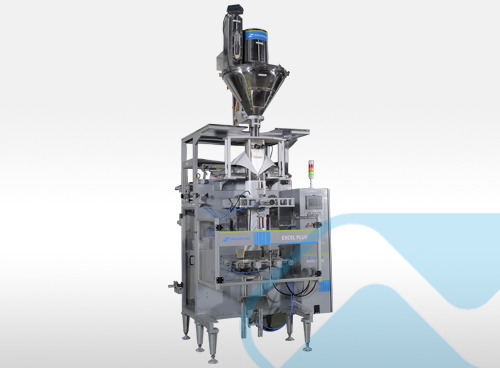

Nichrome, India is leading integrated packaging solutions provider recently came up with a small optimization idea that resulted in impressive benefits for its client. As an expert with over 4 decades in the business, Nichrome understands that the benefits of an optimized package are amplified throughout the distribution cycle.

For a renowned milk producer and marketer in Pune, Nichrome suggested they alter the size of their milk pouch by a few millimeters, making it a rectangular shape. This minute change in the primary packaging not only makes the pouch stand out amongst the other square pouches in the market, it also means more SKUs can be fitted in a typical crate and further, more pouches in a truck. Besides the cost savings in packaging material, even greater savings have resulted from decreased handling, storage and transportation costs.

Conclusion

It’s not easy optimising your package. Ideally, companies should get their marketing, technical and logistics experts to collaborate and develop solutions that enhance efficiency, reduce wastage and lower shipping costs while protecting and promoting your product. Wasteful, environmentally damaging practices are unacceptable — both for business and the earth.

Partnering with a packaging expert like Nichrome can help. From pouch formats and packaging material for primary packaging, secondary packaging and tertiary packaging, Nichrome collaborates to add value and deliver the optimal solution.