The increasing automation of the manufacturing and packaging industry has led to a reduction in production time, reduced wastage, improved system performance and process control.

Manual filling methods are not viable anymore as they result in

low production outputs and losses through spillage - whether you are filling

liquids, solids or powders, in bottles, cans or flexible pouches. Automation

has become pivotal to completing the packaging process in a timely and

cost-effective manner.

BENEFITS OF AUTOMATIC FILLING MACHINES

The automation of the packaging process has created many benefits for packaging companies. There are a number of ways in which automation can improve the packaging process:

Reliability and Consistency

Automatic filling machines permit a

repeatable, reliable and consistent fill cycle - whether the fill is based on a

level of produce, the volume of produce, the weight of produce or another such

measurement. Automatic fillers

remove inconsistencies and eliminate uncertainty from the filling process.

Higher Speeds of Operation

The most apparent benefit of automatic filling machines is the higher speeds of operation that they offer. Automatic fillers use power conveyors and multiple filling heads to fill more containers per cycle - whether you are filling thin, free-flowing products like water and certain powders, or highly viscous products such as jelly or pastes. Hence, the production is faster when using automatic filler machines.

Simple Control Interface

Most modern filling machines come with an easy to operate touchscreen interface and are controlled by PLCs. Indexing times, pump speeds, fill times and other similar parameters can be easily and quickly set up by the operator. The ‘configuration’ is recorded by the PLC so it can be reused in the future.

Versatility

Automatic Filling Machines can be configured to handle a range

of products and container shapes and sizes. The right packaging filling machine offers ease of changeovers with simple

adjustments for companies that package multiple products. This allows the

downtime to be minimised and production maximised.

Future Readiness

Automatic packaging machines need to be acquired keeping the future in mind. Many

modern automatic packaging machines are upgradeable and offer

the potential to increase capacity, add more filling heads and be compatible

with other fillers so a variety of products can be packed on the same machine.

FILLING MACHINES FROM NICHROME

Nichrome offers a cornucopia of food packaging systems, pharma packaging systems and other non-food packaging systems for a range of industry verticals. Nichrome’s offerings in filling solutions include:

These automatic packaging machines are used to fill water and other beverages like milk, juices, soup, alcoholic beverages etc. They can also be configured for filling viscous products such as lassi, yoghurt, sauces, edible oils etc.

These machines utilise spiral feeding technology which enables

proper filling with zero-drip. These machines are ideally suited for filling

powdered items - which can be both free-flowing (sugar, table salt etc) and

non-free-flowing (brown sugar, milk powder etc).

Nichrome’s filling machines can also be used for non-food applications such as

pesticides, starch, dyes, detergents, pharma powders etc.

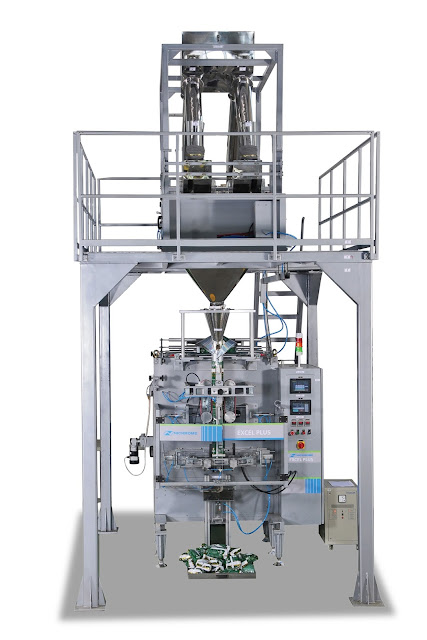

Granule

Filling Machines

Granule products can be filled into sachets and pouches with the use of Nichrome’s granule filling machines. It has a number of applications such as grains, dry dog food, spices etc.

Gel Filling Machines

Designed with a pump head, Nichrome’s gel

filling machines can handle shampoo, hair gels, hair conditioners,

cosmetic creams, thick sauces, honey, toothpaste, car wax and many more

substances quite easily.

Capsule Filling Machines

Nichrome’s pharma packaging machines used in the pharmaceutical industry can efficiently count and pack gelatin capsules - soft or hard. They can also fill coated tablets and pills.

This machine has a number of alternative applications in the

food industry, agriculture, healthcare and chemical engineering fields.

ABOUT NICHROME

Nichrome is a leading provider in India with over four decades of industry experience and thousands of diverse clients across the globe.

The innovative packaging solutions from Nichrome for food, pharma and other applications are supplemented by their solutions for secondary packaging, wrapping and cartoning, bulk packaging and other custom packaging solutions for various applications.

Nichrome’s filling machines are capable of streamlining the entire operation and boosting productivity with their speed, efficiency and reliability. Nichrome provides you with single-

source convenience for both automated packaging machines and end-to-end packaging systems and solutions. This is backed by a dependable

nationwide network for reliable service and genuine spare parts.

Connect with Nichrome today for a diverse selection of solutions, affordable

prices, and knowledgeable customer support.